Our Electric Wire Rope Hoists provide comprehensive lifting solutions

Are you looking for a hoist that actually doesn’t halt your production, breaks down often, or costs too much on maintenance? Get reliable heavy-duty lifts while reducing wear & tear and minimising the risk of equipment or load damage with our Carl Stahl Craftsman’s Electric Wire Rope Hoist.

Whether you’re lifting 500 kg or 150 tonnes, our Electric Wire Rope Hoists are built for smooth, safe, and reliable operation, with the kind of performance that keeps your floor moving efficiently and quickly.

The low maintenance needs, modular structure and enhanced safety features are what make Carlstahl Craftsman the leading Electric Wire Rope Hoist Manufacturers in India. And this can help you solve your lifting problems instantly.

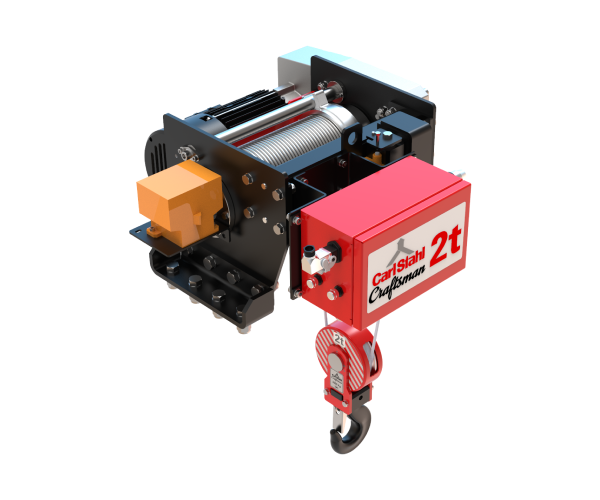

Monorail Hoist

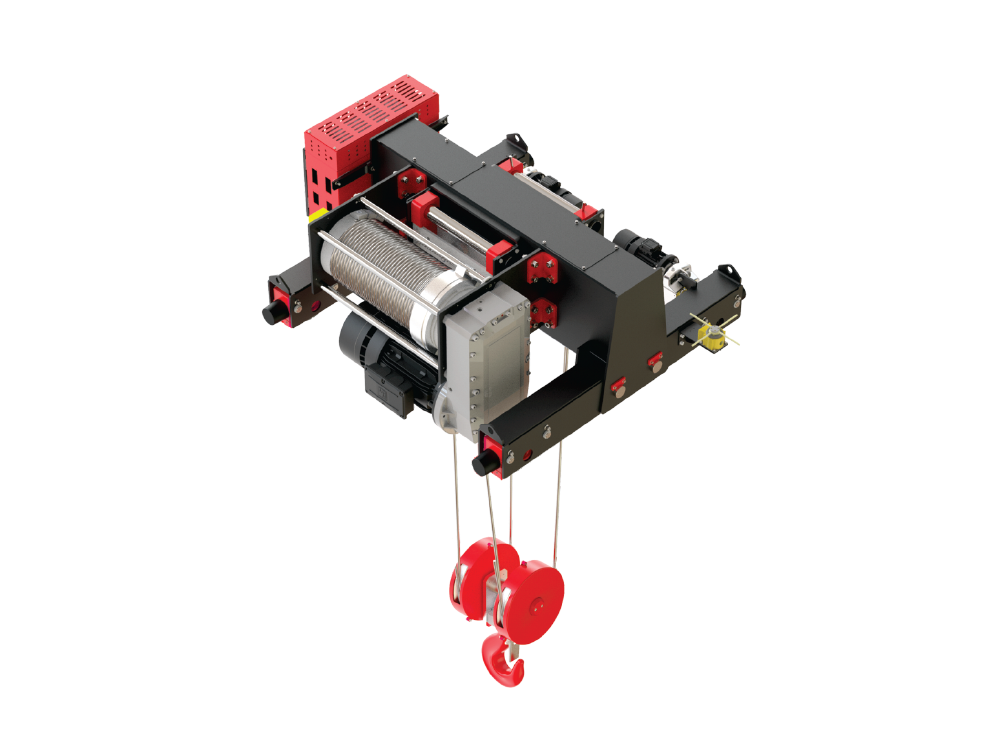

Crab Hoist

Fixed Hoist

What Makes Carlstahl’s Electric Wire Rope Hoist So Efficient?

- Capacity: From 500 kg up to 160,000 kg

- Frame setting: Monorail, articulated hoist with trolley, or double girder, etc., - whichever fits your factory layout

- Speed limit: 1 to 10 m/min (with VFD control for smooth movement)

- Gearbox availability: They are German-built, heavy-duty, and dependable for any capacity

- Motors: IP54/IP65 rated - ready to handle dust, humidity, and long shifts

- Safety features: Limit switches, emergency stop, brake system, remote control, VFD, wheel

- Hoist structure: Rugged, corrosion-resistant frame

- Design: Modular and scalable for quick servicing and fewer breakdowns

Designed To Work Even In Extreme Conditions

We understand the urgency and unpredictability of your shop floor - and we design for that reality and not some ideal working condition.

That’s why every part of our hoist is made for long-term use to perfectly handle even the most demanding situations. If short cycles, continuous lifting, or congested spaces are slowing your work down, this hoist can help you adapt to your workflow quickly.

A Partner To Your Production Success

As the best Electric Wire Rope Hoist Manufacturers, we have built our hoists to keep up with your workload, your pace, and the pressure of real factory life.

From non-stop shifts and heavy loads to tight and chaotic spaces, no matter the challenge - our hoists are always right for the task.

Our hoists are already operating in steel plants, vehicle assembly lines, and equipment manufacturing units across India, proving their value in high-volume, high-stress environments.

Stronger Support for Your Daily Operations

Our hoists don’t just help you with smooth and reliable lifting.

It’s also an investment in your smoother workflow,

safer operation, and fewer disruptions.

01

Reliable performance that keeps your work moving smoothly

No more interruptions during critical lifts or delays caused by mechanical failures. These Wire Rope Hoists can run consistently without any stopping or damage, so your team can focus on production.

02

Safer, smoother operation for your team

The lifting process is more controlled and stable, with no jerks or surprise stops. That means your operators feel more confident, and your floor stays safer without any injuries.

03

Less downtime, fewer service calls

The hoists are built strong and specially designed for quick servicing when needed. The need for maintenance goes down, and uptime goes up.

04

Fits into your space like it belongs there

Every hoist of ours is configured to your setup - even in congested spaces or low headroom areas. That way, you can work with new lifting solutions without the need to rework your factory floor.

05

Responsive local support at any time

With service teams and spares spread across the whole of India, your help is close by. You don’t need to wait for days to fix your problems or chase follow-ups.

06

Long-term savings on service and operation

Fewer breakdowns and faster servicing mean lower running costs - and a hoist that pays for its value with increased uptime. This means you can get the ROI in just a few years.

Designed to Handle Loads - Even At 160 Tons

Our Electric Wire Rope Hoists in India are specially built to make your heavy-duty lifting smooth, easy and reliable. Whether you are lifting a 5-ton machine part, 30-ton or even higher, our Electric Wire Rope Hoists 10 Ton can lift anything smoothly, safely and in control.

With VFD-controlled motion and industrial-grade parts, you can make lifting smoother, with reduced wear and fewer unexpected stops. You can work quickly with these wire rope hoists in your background - running quietly and efficiently, even under short and tight deadlines.

Lifting Your Load And Production At The Same Time

This isn’t just about buying equipment. It’s about making your floor more productive, your team more confident, and your operations more reliable.

If you’re tired of maintaining your old hoist or patching it up every few weeks, now’s the time to switch.

Lift smarter, safer and stronger with Carlstahl Craftsman’s Electric Wire Rope Hoists.

Talk to our technical team to match a hoist with your specific workflow, space constraints, and capacity needs – and get support from the first conversation to post-installation.

Get started now!

FAQ

What is an Electric Wire Rope Hoist?

An Electric Wire Rope Hoist is a heavy-duty lifting machine that uses a wire rope wrapped on a drum to lift or lower loads in factories or workshops.

What load capacities are available for Carlstahl’s Electric Wire Rope Hoists?

Our Hoists are available in a wide range of capacities, from 500 kg (0.5 tonne) to 160,000 kg (160 tonnes), suitable for various industrial lifting needs.

What types of Electric Wire Rope Hoists are offered?

We offer multiple types to match your factory layout, like Single Girder Monorail Hoist, Underslung Hoist - Straight Trolley, Underslung Hoist - Articulated Trolley, Double Girder Crab Hoist, Dual Crab Hoist, and Fixed Hoist.

What is the power supply required for running an Electric Wire Rope Hoist?

The power supply needed for working with an Electric Wire Rope Hoist is 415 Volts, 3 phase, 50 Hz, AC supply along with 460V/60Hz as well.

Are these wire rope hoists suitable for heavy-duty operations?

Absolutely. These hoists are engineered for high-duty cycles and demanding conditions – including heat, dust, and continuous shifts.

What are the safety features included in Carlstahl’s Electric Wire Rope Hoists?

Every Wire Rope Hoist of ours comes equipped with limit switches, emergency stops, brake system, remote control operation, VFD (Variable Frequency Drive) for smooth lifting and load and wheel safety systems.

What is the lifting speed of these hoists?

The lifting speeds of the hoists vary from 1 to 10 m/min, with VFD control for precise and jerk-free movement.

Are these hoists suitable for space-constrained places?

Yes. They are manufactured to fit low headroom and tight spaces without needing major layout changes in your facility.

What industries can these hoists be used for?

Carlstahl Craftsman’s hoists are suitable for steel plants, assembly lines, manufacturing units and any facility requiring heavy, repetitive or precise lifting.

How do I choose the right hoist for my plant?

Our team will help you assess your layout, load profile, and operational requirements to recommend the ideal hoist configuration for your needs.