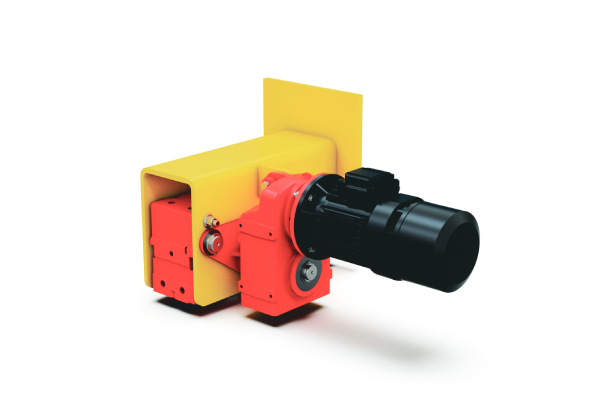

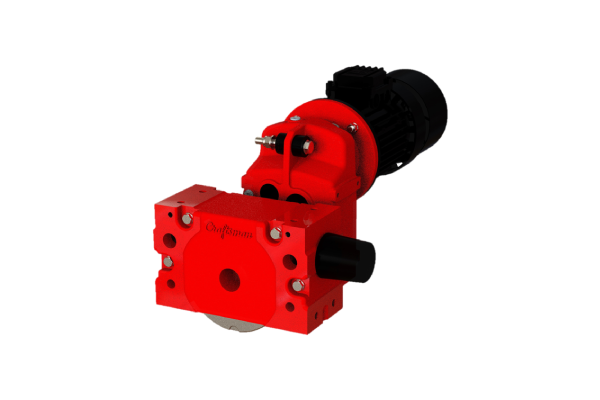

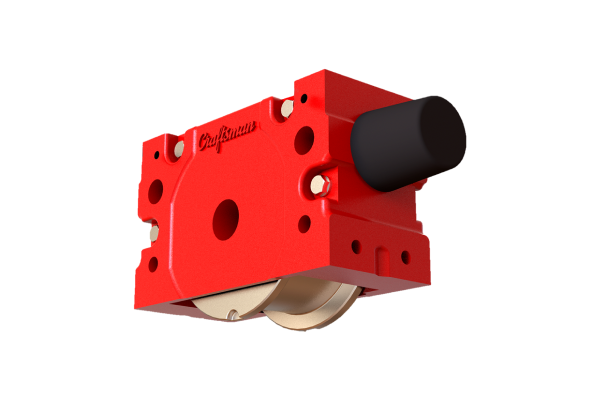

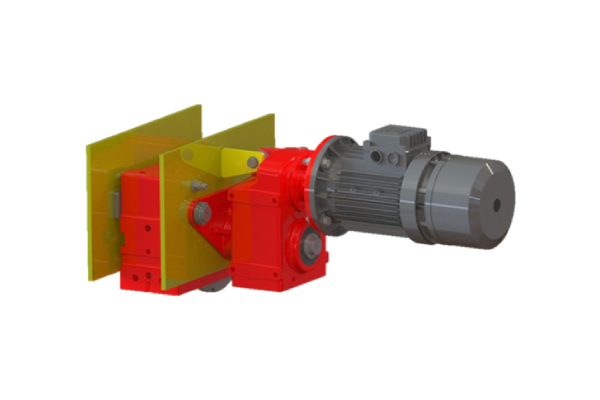

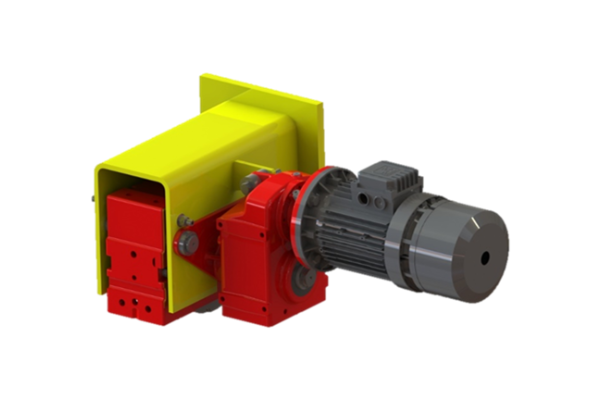

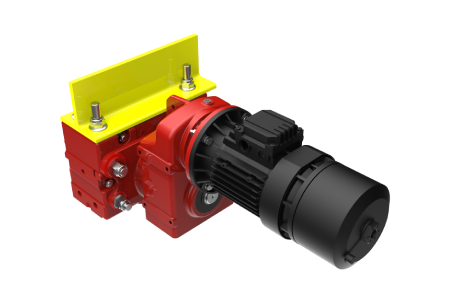

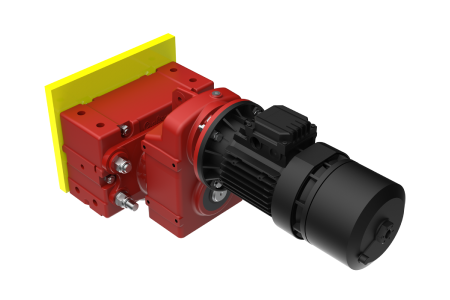

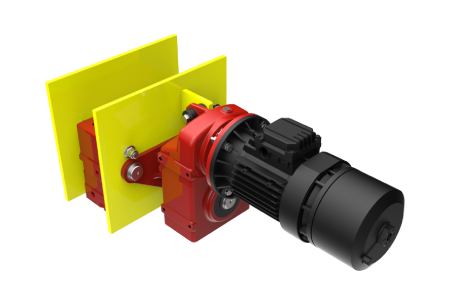

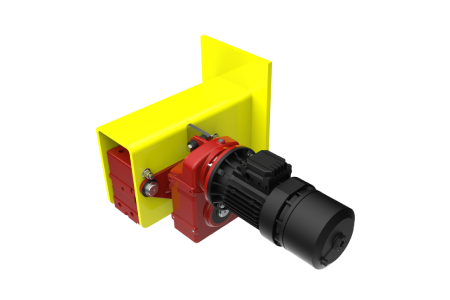

Wheel Block With Geared Motor

Craftsman Wheel Block Systems (CRWB) have been meticulously developed by our team of industry experts, drawing upon years of experience to ensure unparalleled performance and functional reliability. The modular wheel block system from Craftsman presents a swift and cost-effective solution tailored to meet individual requirements. The CRWB Housing, Cover, and Wheel are crafted from spheroidal graphite cast iron, guaranteeing structural stability. Carefully selected bearings are matched to practical load conditions, ensuring low maintenance. Available in various load capacities to address the rapidly evolving industrial demands, Craftsman's wheel block systems are versatile and cater to a wide range of applications, including cranes, hoists, storage systems, transfer carts, conveyors, and lifting platforms.

Standard Specifications

| Crane application | ||||

| Model / Wheel Dia | Pin Connection | End connection | Top Connection | Side Connection |

| CRWB 125 | ✔ | ✔ | ✔ | #Other Applications |

| CRWB 160 | ✔ | ✔ | ✔ | |

| CRWB 200 | ✔ | ✔ | ✔ | |

| CRWB 250 | ✔ | ✔ | ✖ | |

| CRWB 320 | ✔ | ✖ | ✖ | |

| CRWB 400 | ✔ | ✖ | ✖ | |

| CRWB 500 | ✔ | ✖ | ✖ | |

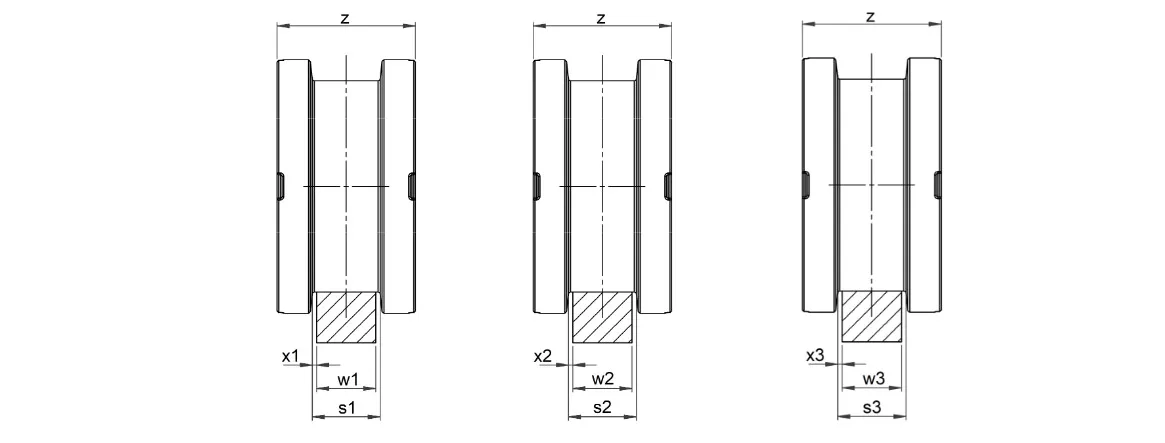

Wheel and Rail Width Selection Details

| Wheel block size /Wheel Diameter | Wheel tread width(s) | Rail width(w) |

Distance per side(x) |

Wheel width (z) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| s1 | s2 | s3 | w1 | w2 | w3 | x1 | x2 | x3 | ||

| 125 | 50 | 62 | - | 32,40 | 45,50,55* | - | 9. 5 | 8.5. 6, 3.5 | - | 82 |

| 160 | 50 | 65 | - | 32,40 | 45,50,55* | - | 9, 5 | 10, 7.5, 5 | - | 97 |

| 200 | 57 | 70 | 82 | 32,40,45 | 50,55,60 | 63, 70, 75* | 12.5, 8.5, 6 | 10, 7.5, 5 | 9.5, 6, 3.5 | 114 |

| 250 | 57 | 70 | 85 | 40, 45 | 50, 55, 60 | 63, 70, 75, 80* | 8.5, 6 | 10. 7.5, 5 | 11, 7.5, 5, 2.5 | 117 |

| 320 | 57 | 70 | 85 | 40. 45 | 50. 55, 60 | 63, 70, 75, 80 * | 8.5, 6 | 10. 7.5, 5 | 11. 7.5. 5. 2.5 | 125 |

| 400 | 70 | 86 | 110 | 50, 55 | 60, 63, 70 | 75, 80, 90, 100 | 10, 7.5 | 13, 11.5, 8 | 17.5, 15, 10, 5 | 150 |

| 500 | 86 | 110 | - | 70 | 75, 80, 90, 100 | - | 8 | 17.5, 15, 10, 5 | - | 150 |

* - Applicable other than cranes

All Dimensions are in mm

Features

- For crane manufacturers, it provides a ready made solution

- Less maintenance , suitable for harsh environment and increased service life

- Closer ranges of diameter with several variables in an organized way makes it suitable

for specific applications in a cost-effective manner - Wheel block can be replaced easily with less effort

- Easy for assembly and disassembly

- Flange wear indicator ensures preventive maintenance without risk

- Time to market is very quick

- Gearbox mounting flange & torque arm mounting which reduces the peak load as a result of travel wheel slip torque.

- Grey iron housings ensure the robustness of the product

- The variants are designed to suit the applications in a cost-effective manner