How The Leading Construction Equipment Manufacturer Improved Operator Efficiency with Carlstahl Craftsman

Products Provided

Light crane systems and Chain & Rope hoists compatible with EOT cranes.

The Problems & Challenges

Even with the EOT cranes, the assembly line was struggling to keep up.

A leading construction equipment manufacturer that builds heavy loaders and backhoes was finding it difficult to achieve precision handling. Even their skilled operators were spending too much of their time moving the heavy parts instead of assembling them.

Even the simplest work was becoming slow and tiring. By the afternoon, operators were already feeling strained and exhausted. The accuracy dropped. Mistakes increased. And the daily tact-time target was also missed too often.

Onboarding new operators also became another issue. The handling process was manual and dependent on physical strength, which meant longer training cycles and inconsistent output.

Hiring wasn’t even an option to be considered. What the operation wanted wasn’t more power but smarter systems that helped the people work efficiently and quickly.

The Solution

To fix the efficiency and meet the deadlines, they reached out to Carlstahl Craftsman for a solution that can fit with their existing EOT cranes.

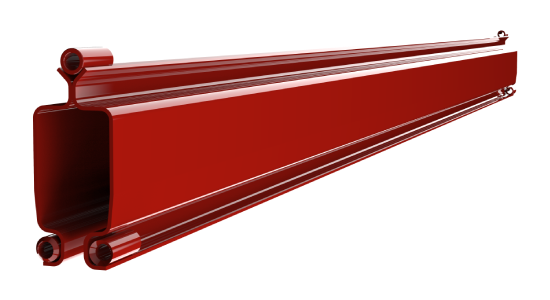

So we came up with a solution - a 2-axis light crane system along with chain and rope hoists built to integrate with the existing EOT cranes already in place.

Designed with lightweight profiles and VFD tech built-in hoists, the system gave operators a smooth and controlled movement across both axes - up and down, vertically and horizontally.

By integrating it with the existing system, it didn’t put a toll on their operating cost or slow things down. That made their work easier and smarter, with less effort.

The Outcome Of The Installation

Within a few weeks, the improvement was clearly visible.

- Operators reported a considerably lower amount of fatigue even after their shift ended.

- With smoother load control, the handling and assembling of parts became more precise. This meant fewer errors, less rework, and a more consistent build quality.

- Tact-time performance improved significantly. Daily output targets were now consistently achieved.

- Even the work efficiency improved. Now the operators could work with quicker speed because the system reduced the complexity and physicality of the task.

The Conclusion

- This wasn’t a big change, but it made a big impact. With Carlstahl’s new light crane system and wire rope and chain hoists in place, the team was able to move parts more quickly, with less physical effort, and with far more precision.

- Operators remained focused for their shifts, and production was never worse, and targets that used to be missed were now achieved every time with a simple solution that helped the entire assembly line work smarter.

- For any business trying their best to be more efficient without increasing overhead or running slower, this type of upgrade shows just how much the right lifting equipment can unlock.